Specialty Areas

Mory’s Exclusive Production Facilities

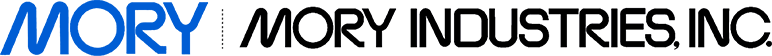

Our Machinery and Metal Mold Manufacturing Division employs the most advanced machinery.

Our machinery factory is fully equipped with the most advanced machine tools and metal mold manufacturing equipment. Here, we design and build virtually all our own tube manufacturing machinery (piping machines, etc.) as well as our own metal molds and rolls. This capability has contributed substantially to our rapid growth.

Mory’s Exclusive Material Fabrication

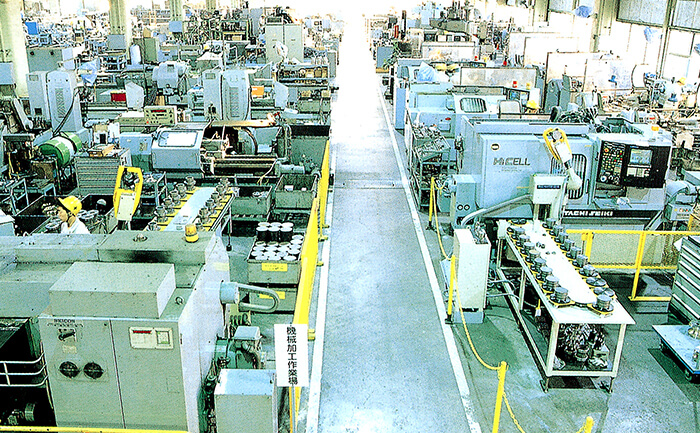

Refining our “upstream strategy”

One problem commonly faced by manufacturers of welded pipe and tubing is the low level of added value resulting from the limited processing involved. We have executes the material processing in the cold re-rolling mill of the cold-rolled strip, bright annealing furnace, slitter by in-factory and it obtains the result.

Products Fabricated from Stainless Steel Tubing

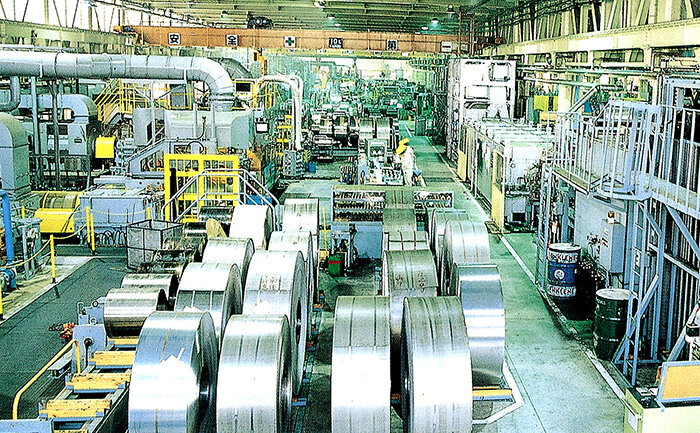

Products fabricated from stainless steel tubing

Fabrication with stainless steel tubing, particularly clad tubing, is technically challenging, so most fabricators deliberately avoid it. Seeing an opportunity, Mory Industries vigorously promoted research on fabrication technology. As a result, we have succeeded in expanding our stainless steel product market to include construction materials, hardware, furniture, and automotive parts. Equally important, We have added greater value.

Ensuring Efficiency with Multistory Facilities

Our factory buildings are two or three stories high.

Our factory buildings (including those of our affiliates) are two or three stories high. Each plant is equipped with a ramp allowing truck access to the upper stories.

A Service System that Meets Complex Customer Needs

Speed and flexibility are the keys.

Large enterprises are plagued by a lack of speed and flexibility. Medium-sized enterprises such as Mory Industries can exploit their advantage in this area. For example, our service system, with its highly trained service personnel, satisfies every detailed need of our customers in terms of delivery, quality, technical service, after-sales service, and many other areas.